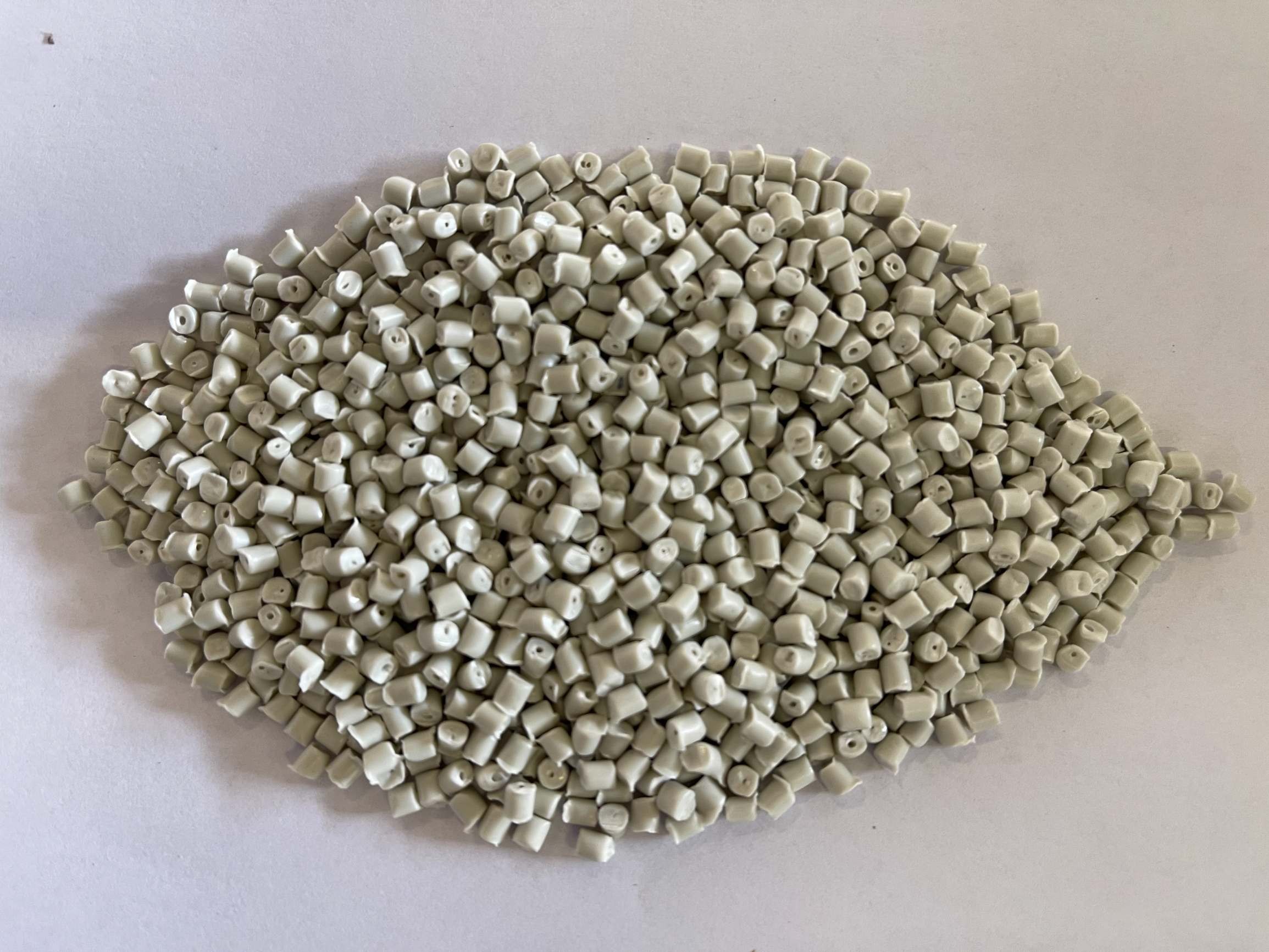

PP regranulate

Our PCR r-PP (Polypropylene) Recycled Material is available in a range of light to dark colors. The different qualities are available in a wide range of MFI (Melt Flow Index) values and are suitable for film blow molding, (sheet) extrusion, injection molding, and blow molding applications. GRS, OBP, and FDA food-grade certified qualities are available.

Qualities:

- Conventional

- GRS – Global Recycled Standard

- OBP – Ocean Bound Plastic

- FDA – Food-Grade

Color Examples:

- Transparent

- Black

- Natural

- Various Colors

Environmental Friendliness in Business: How Recycled Polypropylene Supports Companies in Becoming More Sustainable

Recycled polypropylene (r-PP) is a valuable alternative to newly produced polypropylene (PP), relevant for B2B customers across various industries. By using recycled polypropylene to manufacture products, companies can offer a more sustainable and environmentally friendly alternative to conventional plastic products.

For companies that generate large amounts of plastic waste, recycled PP provides a way to utilize this waste effectively while reducing environmental impact. With growing demand for eco-friendly products across many sectors, recycled PP is becoming increasingly relevant for B2B clients.

Recycled Polypropylene in Focus: What You Should Know

Polypropylene (PP) is a thermoplastic polymer similar to HDPE in terms of its properties and structure. Due to its characteristics, such as low density, high strength, and resistance to chemical substances, PP is widely used in various industries, including automotive, packaging, and construction. Typical applications for PP include food packaging, medical packaging, automotive parts like bumpers and dashboards, as well as pipes and films.

Post-consumer recycled polypropylene is produced from used polypropylene. The plastic waste is first sorted, cleaned, and shredded before being processed into regranulate. r-PP has similar properties to new PP material but is significantly more environmentally friendly, contributing to the reduction of plastic waste and requiring fewer resources and less energy for production.

Cost-Effective Sustainability: The Benefits of Recycled Polypropylene for B2B Clients

r-PP offers numerous advantages for B2B clients. It allows for material cost savings since r-PP is often less expensive than new polypropylene. Additionally, companies that manufacture or use products made from recycled polypropylene can achieve their sustainability goals and enhance their image as environmentally conscious organizations. r-PP is also an eco-friendly option for customers who prefer sustainable products and wish to contribute to environmental protection. According to a 2020 study by the Association of Plastic Recyclers, recycled PP is a more environmentally friendly alternative to new raw materials, with CO2 emissions up to 70% lower than those of virgin granulate.

Versatile Polypropylene: How r-PP is Used Across Various Sectors

Recycled polypropylene is an attractive choice in many industries and applications due to its sustainability and cost-efficiency. In the packaging industry, it is often used for food and beverage containers due to its stability and potential food-grade certification. In the automotive industry, it is utilized for manufacturing parts such as bumpers, dashboards, and wheel covers. It can also be used in the construction industry for making pipes, cable conduits, and insulation.

Further examples of r-PP applications in the B2B sector include interior trims and child safety seats. Interior trims in vehicles are often made from polypropylene because it is lightweight, stable, and resistant to high temperatures and chemicals. Here, r-PP provides a more eco-friendly alternative to new PP. r-PP can also be used in child safety seats, as it is safe and robust, meeting regulatory requirements for reducing harmful substances.

Recycled polypropylene enables companies to demonstrate environmental responsibility and contribute to reducing waste and emissions. By using recycled PP granulate and regranulate, B2B clients can not only save costs but also meet their sustainability objectives and enhance their reputation as responsible businesses.

No Compromises on Quality: Standards and Certifications for r-PP

To ensure the quality of PP recyclate, various certifications are available. The PP we offer meets the highest quality standards and is optionally certified by the Food and Drug Administration (FDA) and the Global Recycled Standard (GRS), as well as Ocean Bound Plastic (OBP).

Food-Grade PCR r-PP Regranulate

Our food-grade r-PP regranulate is approved for use in products with food contact by the American FDA. It can serve as a replacement for new PP plastic in many applications.

It is manufactured from high-quality cups from post-consumer recycling (PCR), processed through a tailored method to ensure the best quality and consistent performance.

To ensure food-grade safety, the input material consists solely of food-grade post-consumer plastics, and the recycling facility is certified by the FDA.

The FDA has no objections to the use of up to 100% recycled content in the manufacture of items under FDA use conditions (COU) E to G.

Additionally, the r-PP regranulate is certified by the Global Recycled Standard (GRS), ensuring that it is indeed PCR r-PP from source to product.

The GRS certification also ensures that recycling is conducted under high environmental and labor protection standards.

The FDA recommends the following use conditions:

- Items (e.g., single-layer trays, containers, boxes, and clam shells) intended for contact with raw fruits, vegetables, and shell eggs under COU E to G.

- Items (e.g., containers) intended for use with dry food supplements, retail carry bags (shopping bags), and secondary and tertiary packaging films for all food types under COU E to G.

- Non-food contact layers in multi-layer packaging intended for all types of food under all COUs, provided that the PCR PP is separated from food by an effective barrier.

This food-grade plastic recyclate complies with the following regulations:

- LNO received from the US FDA

- EU REACH Regulation (EC) No. 197/2006 Article 33 (1) (SVHCs)

- RoHS Annex II of 2011/65/EU and Amendment (EU) 2015/863 (Heavy Metals)

- EN71-3:2019

Didn’t find what you were looking for or have more questions? We are happy to help you source recycled PP based on your procurement specifications. Please email us at:

info@atm-gmbh.com and get in touch with us. Or use the form below to request a sample.

Delivery Conditions: FCA, FOB, CIF, CFR, based on customer request

Custom Packaging: Packaging: Bulk packaging, 25 PP bags, also 1 MT jumbo bags

Minimum Order Quantity: 20 tons