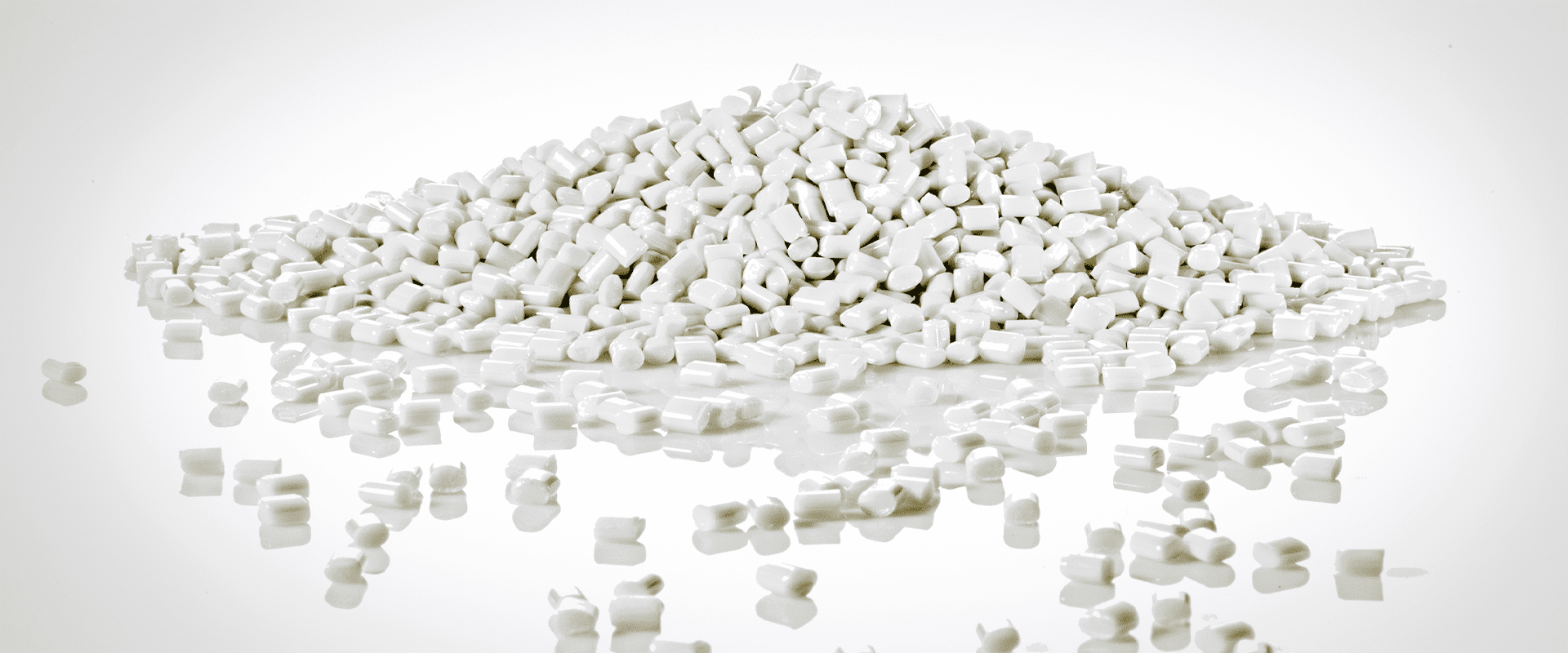

PET regranulate

PCR r-PET (Polyethylene Terephthalate) is available in crystallized white and green. Products made from crystallized white r-PET are transparent. Applications include bottles (Bottle-to-Bottle), BOPET films, injection molding, and polyester. GRS, OBP, and food-grade certified qualities are available.

Revolution in the Material Sector – PCR r-PET – The Future of Polyethylene Terephthalate

In an era where sustainability and environmental protection are becoming increasingly important, the material industry has also undergone significant changes. Post-Consumer Recycled (PCR) r-PET (Polyethylene Terephthalate) represents an exciting step into the future, offering both environmental and economic benefits.

What is PET Recycled Material?

PET recycled material comes in various types, differing in purity and color. Some types of PET recycled materials also have special properties, such as high stiffness. It is impact-resistant and has high shape stability at temperatures above 80°C. PET recycled material is used in a wide range of applications, including packaging, films, textiles, automotive parts, and furniture.

How Does PET Recycling Work?

The PET recycling process starts with the collection of PET waste, often PET bottles in Germany, followed by initial sorting. The PET material is washed and then processed into flakes. The flakes are then washed again at high temperatures before further sorting, separating PET flakes from other flakes and sorting by color.

In the next step, the PET flakes are melted and processed into granules. For specific applications that demand high additional requirements for the PET granules, the Solid State Polycondensation (SSP) process may be used at the end. This adjusts the Intrinsic Viscosity (IV) to match the value of new PET granules, while the color of the PET regranulate remains unchanged. The resulting Post Consumer Recycling r-PET can, for example, be used for food-grade bottles.

Properties of PET Recycled Material

Recycled PET, also known as r-PET, has similar properties to new PET depending on the quality and can be used for various applications.

Some differences between PET recycled material and new material include:

- Color and Transparency: Since recycled plastic comes from different sources, the color of PET recycled material can vary. However, transparent PET recycled material can be produced through color sorting for various applications.

- Molecular Weight: Different applications of PET require different degrees of polymerization, which can be achieved by changing process conditions, such as the aforementioned SSP process.

- Purity: PET recycled material may contain trace amounts of other plastics or contaminants that were not completely removed during the recycling process. However, strict standards ensure the purity of recycled PET to make it suitable for specific applications.

The Shift to a Circular Economy: Quality Control in PET Recycled Material Production

Quality control is crucial in the production of PET recycled materials. PET material is regularly checked for purity and properties to ensure it meets the requirements for the intended application. Various tests and analyses are conducted for this purpose.

Certifications such as the Global Recycled Standard (GRS) confirm that the material comes from Post Consumer Recycling (PCR) and that environmental and labor protection standards are met, while Ocean Bound Plastic (OBP) indicates that the recycled PET comes from marine regions with poor waste management.

FDA Certified r-PET

Our food-grade r-PET is approved for use in products with direct food contact by the American Food and Drug Administration (FDA) and the European Food Safety Authority (EFSA). This allows it to serve as a replacement for new PET plastic in most applications.

It is produced from high-quality water bottles from Post Consumer Recycling (PCR) that are processed in a customized process to ensure the best quality and consistent performance.

The FDA has no objections to using up to 100% recycled content in the manufacture of items for contact with all types of food according to the FDA Conditions of Use (COU) B to H. Additionally, r-PET is certified by the Global Recycled Standard (GRS), ensuring that it is indeed PCR r-PET from source to product.

The FDA suggests the following usage conditions:

- r-PET High IV pellets for use with up to 100% recycled content in the manufacture of items for contact with all types of food according to COU B to H.

- Regular r-PET pellets for use with up to 100% recycled content in the manufacture of items for contact with all types of food according to COU C-G.

- r-PET flakes and regular r-PET pellets for use in the manufacture of a non-food contact layer of a multi-layer food packaging, provided that a food contact layer is new PET with a thickness of ≥ 25 µm (~0.001 inch) for use at room temperature and below (COU E-G), and pure PET with a thickness of ≥ 50 µm (~0.002 inch) for use at higher temperatures, including use as an oven-safe container for cooking food at 150°C for 30 minutes (COU A-H), provided that only food packaging materials are used in the production of the recycled PET layer.

Processing and Usage Conditions of EFSA

The starting material consists of hot-washed and dried Polyethylene Terephthalate flakes from collected PET containers, of which no more than 5% are from non-food applications. The flakes are heated in a continuous reactor under vacuum before being extruded. After reviewing the presented challenge test, the panel concluded that the reactor for Step 2, for which a challenge test was provided, is crucial for determining the decontamination performance of the process. The operating parameters to control the performance of this step are temperature, pressure, and residence time. It has been demonstrated that this recycling process can ensure migration of potential unknown contaminants into food, remaining below the conservatively modeled migration value of 0.1 µg/kg food, derived from the exposure scenario for infants when using 100% recycled PET.

Therefore, the panel concluded that the recycled PET produced by this process, used up to 100% for the manufacture of materials and articles for contact with all types of food, including drinking water, for long-term storage at room temperature, with or without hot filling, is considered safe. Items made from this recycled PET are not intended for use in microwave ovens and conventional ovens; such uses are not subject to this evaluation.

This food-grade plastic recycled material complies with the following regulations:

- FDA Regulation 21 CFR § 177.1630 [Sections (f) & (g)] in the currently valid version(s)

- European Union (EU) EC10/2011 (including the latest amendments from 2019)

- EU REACH Regulation (EC) No. 197/2006 Article 33 (1) for SVHCs (219) from the 25th SVHC in the candidate list (2021.07)

- ROHS DIRECTIVE (2011/65/EU): Restriction of the use of certain hazardous substances in electrical and electronic equipment

- ROHS DIRECTIVE (2011/65/EU) and delegated EU Directive of the Amendment Commission 2015/863 effective July 22, 2019: Phthalates content

- CONEG legislation in the USA as well as EN71/2015/863/EU (Heavy metals)

Benefits, Challenges, and Solutions in the Use of PET Recycled Material

The use of PET recycled materials offers many benefits for companies interested in sustainable production. By using PET recycled materials, the need for new raw materials is reduced, conserving resources. Greenhouse gas emissions are also lowered because less energy is required to produce new raw materials. According to a 2020 study by the Association of Plastic Recyclers, PET recycled material is an environmentally friendly alternative to new raw materials, as the CO2 emissions are about 60% lower than those of new granules.

In the packaging and film sector, PET recycled materials can be used for making food packaging, beverage bottles, or cosmetic containers. In the textile industry, r-PET can be used for clothing or bags, often mixed with other recycled or sustainable fibers to improve the properties of the final product.

In the technical industry, PET recycled materials can be used, for example, for making enclosures for electronic devices or for durable parts like gears or door handles. The use of recycled materials in these areas helps conserve resources and supports companies in achieving their sustainability goals.

Bottle-to-Bottle Recycling

A major trend is also Bottle-to-Bottle recycling, which focuses on producing high-quality, food-grade PET recycled material from old PET bottles, which are then used to make new PET bottles. Two modern processing methods are employed for this. In the first process, called URRC (named after the United Resource Recovery Corporation), the flakes are intensively cleaned in an energy- and material-efficient manner without melting. In the second process, known as the Starlinger method, PET flakes are melted, filtered, and then granulated to achieve food-grade quality that meets the highest food standards.

In the future, the potential of PET recycling and recycled materials will continue to grow as the demand for sustainable products and production processes increases. Optimized sorting and cleaning as well as the use of new technologies can help further improve the quality of PET recycled materials, thus encouraging more companies to use recycled materials.

Need assistance or have questions? We are happy to help you source recycled PET based on your purchasing specifications. Please send an email to:

info@atm-gmbh.com and get in touch with us. Or use the form below to order a sample.

Delivery conditions: FCA, FOB, CIF, CFR, based on customer request

Custom packaging:

Packaging: Bulk packaging, 25 PP bags, also 1 MT Jumbo bags

Minimum order quantity: 20 tons