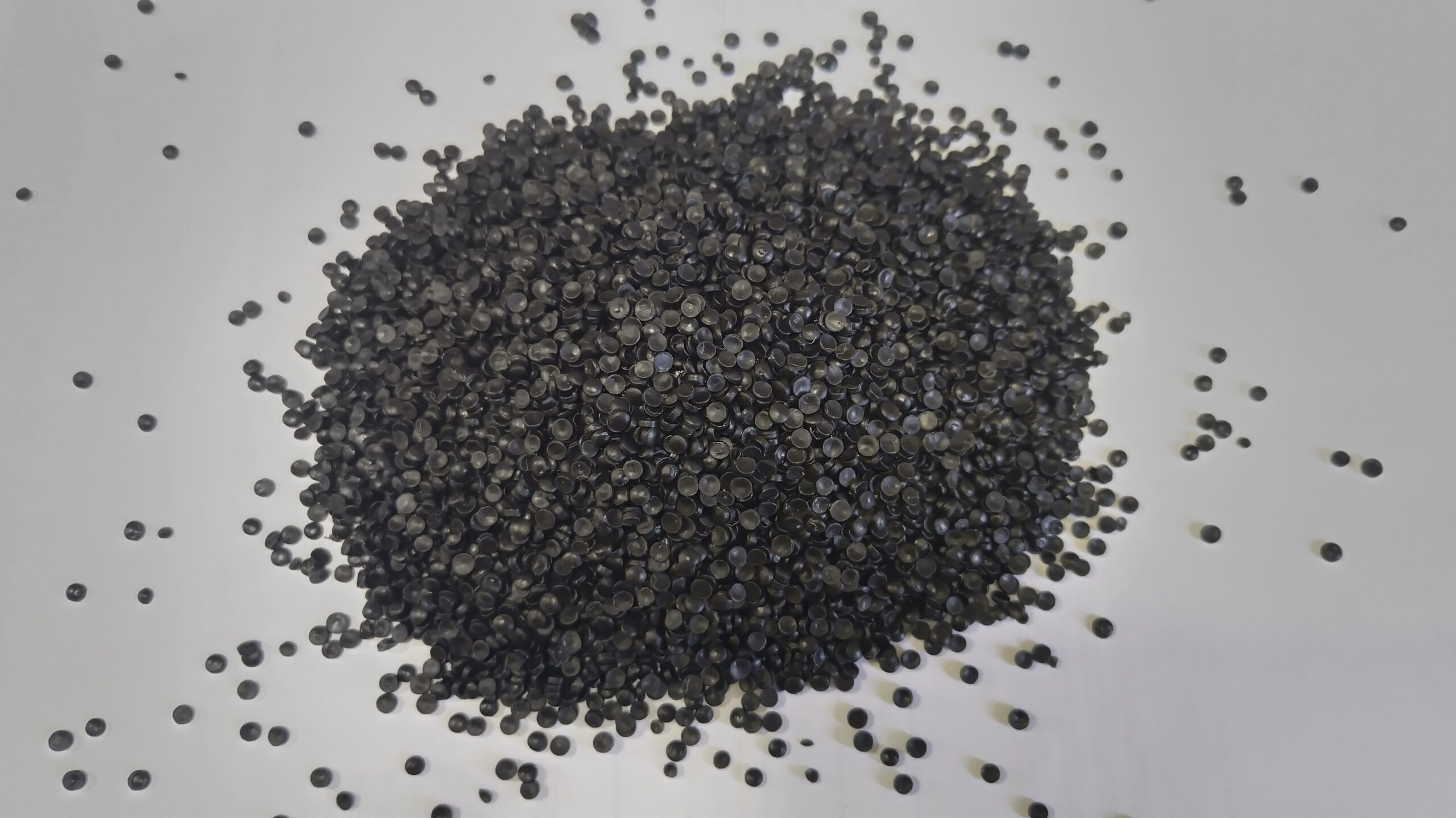

HDPE Regranulat

PCR r-HDPE (High-Density Polyethylene) is available in light to dark colors. It is suitable for film blowing, blow molding, and injection molding applications. GRS, OBP, and FDA food contact-certified grades are available.

Grades:

- Conventional

- GRS – Global Recycled Standard

- OBP – Ocean Bound Plastic

- FDA – Food Contact Safe

Color Examples:

- Transparent

- Black

- White

- Natural color

- Various colors

Sustainability in Focus – Why HDPE Recycling is the Future

For companies, using HDPE recyclate is an excellent way to achieve their sustainability goals and reduce their ecological footprint. By using recycled HDPE plastic instead of new HDPE, companies can conserve resources, reduce waste, and lower production costs. Additionally, there is a growing demand from consumers and regulatory agencies for more environmentally friendly products. By using PCR HDPE regranulate and regrind, companies can present themselves as part of the circular economy and meet their sustainability goals.

HDPE – A Flexible and Durable Plastic

HDPE (High-Density Polyethylene) is a thermoplastic plastic known for its high density, strength, and stiffness, making it suitable for many applications. HDPE is produced through the polymerization of ethylene and is typically opaque and resistant to many chemicals and moisture. HDPE has excellent tear resistance and is also UV-resistant, making it a suitable choice for outdoor products. Applications of HDPE include packaging, containers, pipes, toys, and (outdoor) furniture. Due to its versatile properties and its potential for reuse as a recycling material, HDPE recyclate is a key component for companies in the plastics industry, also in achieving environmental goals.

Cost-Effective, Environmentally Friendly, and Certified – The Advantages of HDPE Recyclate

Using post-consumer recycled HDPE recyclate offers various benefits, including cost savings compared to new material. According to a 2020 study by the Association of Plastic Recyclers, recycled HDPE is also considered a more environmentally friendly alternative to new raw materials, as CO2 emissions are up to 70% lower than with new granulate. Additionally, there are quality standards and certifications to ensure that the material meets industry requirements and standards.

Food-Grade HDPE Regranulate

Our food-grade HDPE regranulate is approved by the American Food and Drug Administration (FDA) for use in products with food contact. It can serve as a substitute for new HDPE plastic in many applications.

It is produced from high-quality post-consumer recycling (PCR) containers, which are recycled in a tailored processing process to ensure the best quality and consistent performance.

To ensure food safety, the input material consists exclusively of food-grade old plastics, and the recycling plant is FDA certified. The FDA has no objections to the use of up to 100% recycled content in the manufacture of items according to FDA use conditions (COU) E to G.

For more information on the FDA and its quality standards, please visit our certificate information pages.

In addition to our food-grade HDPE, we also offer other grades with different certifications, such as Global Recycled Standard (GRS). This ensures that from the source to the product, it is indeed PCR HDPE.

The GRS certification also ensures that recycling is conducted under high environmental protection and occupational safety standards.

The FDA recommends the following use conditions:

- Items (e.g., single-layer bowls, containers, boxes, and clam shells) intended for contact with raw fruits, vegetables, and shell eggs, according to use conditions (COU) E to G.

- Items (e.g., containers) intended for use with dry dietary supplements, retail carry bags (shopping bags), and secondary and tertiary packaging films intended for use with all food types under COU E to G.

- Layers in multi-layer packaging not in contact with food, intended for use with all types of food under all COUs, provided that the PCR HDPE is separated from the food by an effective barrier.

This food-grade plastic recyclate complies with the following regulations:

- LNO from the US FDA

- EU REACH Regulation (EC) No. 197/2006 Article 33 (1) (SVHCs)

- RoHS Annex II of 2011/65/EU and Amendment (EU) 2015/863 (Heavy Metals)

- EN71-3:2019

Versatile Applications – How HDPE Recyclate Promotes the Circular Economy

HDPE plastic is used in various applications, including packaging, pipes and fittings, toys, and furniture. In the packaging sector, HDPE material is often used for food packaging, shampoo bottles, and plastic bags. For pipes and fittings, it is used in the production of drinking water and wastewater pipes, as well as in agriculture. Toy manufacturers use HDPE recyclate for making building blocks, figures, and other toys. In the furniture sector, it is used to produce garden furniture, waste bins, and other outdoor furniture.

Innovative and Sustainable – The Future of HDPE Recyclate in the Plastics Industry

The use of HDPE recyclate is expected to continue to increase as companies strive to meet their sustainability goals and reduce the use of new materials. However, a challenge is the availability of sufficient quantities of high-quality HDPE recyclate, particularly in countries with limited recycling infrastructures. Therefore, it will be important to continue investing in the development and expansion of recycling and collection systems to meet the demand for high-quality HDPE recyclate in the industry.

Didn’t find what you were looking for or have further questions? We are happy to help you source recycled HDPE based on your purchase specifications. Feel free to email us at:

info@atm-gmbh.com and get in touch with us. Or use the form below to order a sample.

Delivery Terms: FCA, FOB, CIF, CFR, based on customer request

Custom Packaging: Available

Packaging: Bulk, 25 PP bags, also 1 MT Jumbo bag

Minimum Order Quantity: 20 tons