Polyethylene terephthalate

(PET) (PET-A), (PET-C), (PET-G)

Other names: Poly(ethylene glycol terephthalate); Polytetramethylene terephthalate; Poly(oxyethylene oxyterephthaloyl)

Abbreviation: PET, occasionally also PETP

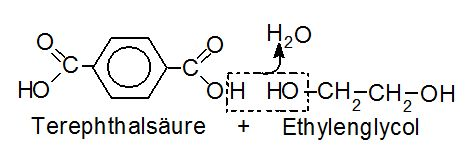

Polyethylene terephthalate (PET) is a linearly structured, thermoplastic polymer. It is based on the ester of terephthalic acid (benzene-1,4-dicarboxylic acid) with ethylene glycol (ethane-1,2-diol). Older PET synthesis methods were based on the transesterification of dimethyl terephthalate with ethylene glycol. Today, PET synthesis is almost exclusively carried out by the direct esterification of terephthalic acid with ethylene glycol at temperatures between +220 and +260 °C, with water being released as indicated in the following reaction scheme:

The subsequent reaction step, polycondensation of the monomeric terephthalic acid ethylene glycol ester to polyethylene terephthalate (PET), proceeds almost completely with the aid of a catalyst.

There are three types of PET: PET-A, PET-G, and PET-C.

Each type exhibits different material properties, such as variations in density, melting temperature, and deformation temperature.

Amorphous PET-A

Transparent amorphous PET-A offers better dimensional stability, including better impact resistance. However, the hardness and stiffness of this PET type are lower than those of PET-C. Additionally, its application limits are narrower, as amorphous PET-A can only be used between -40 and 60 degrees Celsius. Under exclusion of air, it can be used up to 100 degrees Celsius. The reason for the lower temperature range is that crystallization occurs at 80 degrees Celsius. Although this can be reduced through thermal post-treatment or stretching, it cannot be completely avoided. Amorphous PET is fully transparent up to a wall thickness of five millimeters. Compared to PET-C, amorphous PET-A has significantly better resistance to perchlorinated hydrocarbons.

PET-C

PET-C has high stiffness and strength but shows very low impact resistance. Additionally, polyethylene terephthalate C does not tend to deform through creep. Naturally, this technical plastic has good abrasion resistance. The thermal load capacity of PET-C ranges between 20 and 120 degrees Celsius, and short-term exposure up to 200 degrees Celsius is possible. When oxygen is excluded, a permanent thermal load of up to 135 degrees Celsius is possible. However, at 80 degrees Celsius, there is a drop in the modulus of elasticity.

PET-G

PET-G becomes tough and particularly shape-stable with the addition of glycol, making it highly suitable for small containers such as cans and bottles.

Applications of Polyethylene Terephthalate (PET)

PET is mainly used for blow-molded bottles, having largely replaced the previously common glass or metal packaging. PET beverage bottles are sold with different wall thicknesses; for example, bottles with thin walls are single-use, while thick-walled bottles are used as reusable bottles.

Of course, PET is also used in other areas, such as carrier material for magnetic tapes and photographic films, adhesive tapes, electrical insulating films, and writing films. PET-C parts are found in various small devices. PET is also used for rollers, gears, furniture laminates, and fibers.

Technical Data

Due to the differing degrees of crystallization and, consequently, many technical parameters, the listed data for PET-A and PET-C are only rough guidelines. They may significantly deviate from the values provided by the manufacturers of the respective products.

| PET-A | PET-C | |

|---|---|---|

| General Properties | ||

| Density | 1.34 g/cm³ | 1.40 g/cm³ |

| Color | Up to approx. 5mm: clear | White |

| Thermal Properties | ||

| Thermal conductivity | 0.24 W/K · m | 0.24 W/K · m |

| Oxygen index (LOI) | 21% | <25% |

| Flame class UL 94 | HB | HB |

| Continuous use temperature range | -40 °C to +60 °C | -20 °C to +100 °C |

| Max. short-term temperature load | +80 °C | +135 °C |

| Short-term under exclusion of oxygen | +100 °C | +180 °C |

| Electrical Properties | ||

| Dielectric constant (50 Hz) | 3.4 | 3.4 |

| Dielectric constant (1 MHz) | 3.2 | 3.2 |

| Dielectric loss factor (50 Hz) | 2 x 10⁻³ | 2 x 10⁻³ |

| Electrical breakdown strength | 25 kV / mm | 25 kV / mm |

| Specific volume resistance | 2 x 10¹³ Ω · cm | 2 x 10¹³ Ω · cm |

| Surface resistance | 6 x 10¹⁴ Ω | 6 x 10¹⁴ Ω |

| Tracking resistance | 350 | 350 |

| Mechanical Properties | ||

| Yield stress | – | 80 MPa |

| Elongation at break | – | 70% |

| Tensile modulus (E-modulus) | – | 2.8 x 10³ MPa |

| Shore hardness D | – | 80 |

Delivery conditions: FCA, FOB, CIF, CFR, based on customer request

Custom packaging: Available

Packaging: Bulk packaging, 25 PP bags, also 1 MT jumbo bags

Minimum order quantity: 20 tons

Didn’t find what you were looking for, or still have questions? We would be happy to help you source recycled PC based on your purchasing specifications. Feel free to send an email to:

info@atm-gmbh.com and get in touch with us. Or use the form below to order a sample.